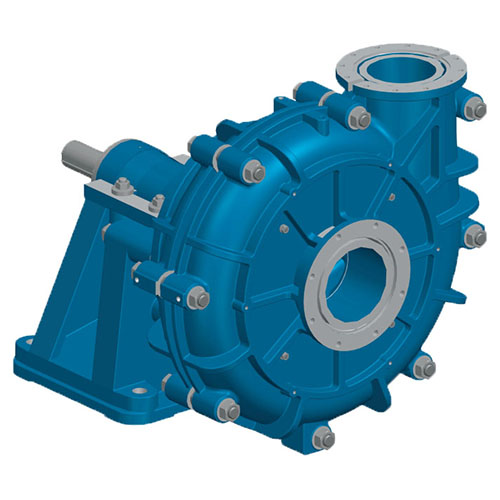

Unlined Horizontal Pumps for Gravel is featured by a metal casing with no separate liners and no elastomer wear parts. The design features a hard metal casing and wear components and is capable of passing extremely large particles. They are typically used for pumping gravel, dredging, or pumping solids that are too large to be handled by type MSH pumps. MSG gravel pumps adopt larger impellers and heavier casing construction. Sizes range from 100mm to 400mm.

Material Construction:

| Description | Standard Material | Optional Material |

| Impeller | A05 | |

| Door | A05 | |

| Bowl | A05 | |

| Front Cover | A05 | |

| Back Liner | A05 | |

| Shaft | Carbon Steel | SUS304, SUS316(L) |

| Shaft Sleeve | 3Cr13 | SUS304, SUS316(L) |

| Shaft Seal | Gland Packing Seal | Expeller Seal, Mechanical Seal |

Applications of Unlined Horizontal Pump for Gravel:

Sand and Gravel; Hydraulic Mining; Sugar Beet & Other Root Vegetables; Slag Granulation; Tunnelling; River Dredging.

Specifications:

Pump | S×D | Allowable | Clear Water Performance | Impeller | |||||

Capacity Q | Head | Speed | Max.Eff. | NPSH | No. of | Vane Dia. | |||

m3/h | |||||||||

MSG-4D | 6×4 | 60 | 36-250 | 5-52 | 600-1400 | 58 | 2.5-3.5 | 3 | 378 |

MSG-6E | 8×6 | 120 | 126-576 | 6-45 | 800-1400 | 60 | 3-4.5 | 391 | |

MSG-8F | 10×8 | 260 | 216-936 | 8-52 | 500-1000 | 65 | 3-7.5 | 533 | |

MSG-10G | 12×10 | 600 | 360-1440 | 10-60 | 400-850 | 65 | 1.5-4.5 | 667 | |

MSG-12G | 14×12 | 600 | 432-3168 | 10-64 | 300-700 | 68 | 2-8 | 864 | |

MSG-16T | 18×16 | 1200 | 720-3600 | 10-50 | 250-500 | 72 | 3-6 | 1067 | |

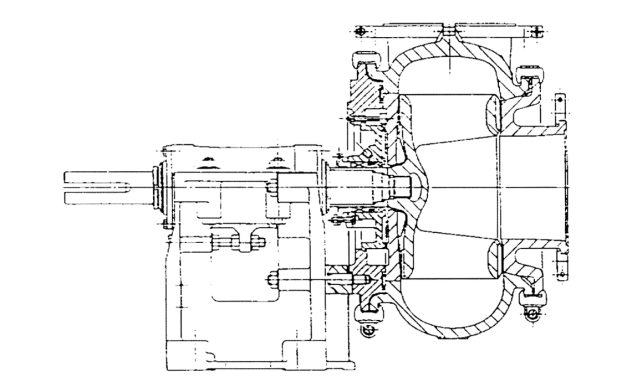

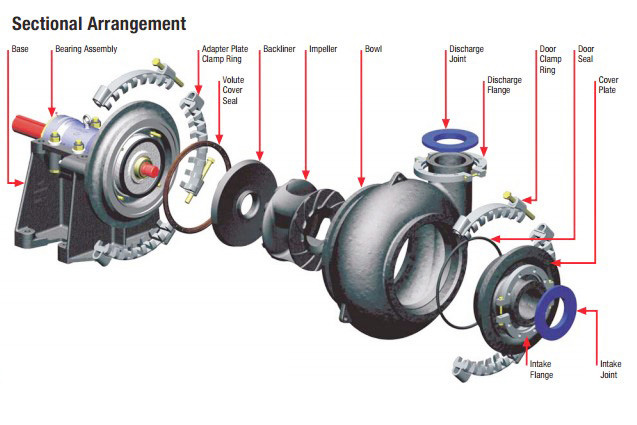

Structure:

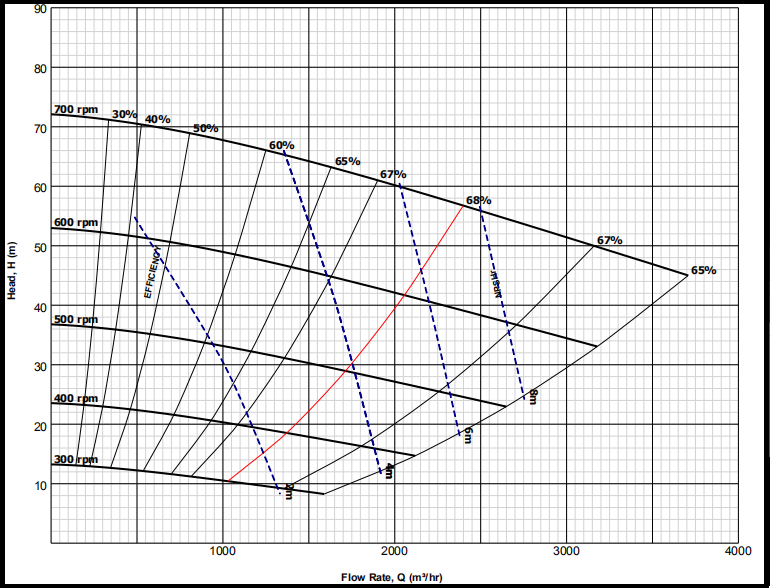

Performance Curve:

Related Products

Yes, we are a manufacturer of slurry pump in China since 2008.

Yes, OEM/ODM are available.

T/T Bank Wiring, L/C, Western Union, Moneygram, Paypal.

By sea, air, railway.

Slurry pumps typically have a volute casing which is rubber lined, as well as a rubber lined impeller in order to minimise wear to internal metal parts. As slurries can be highly abrasive, and travel at high velocity the rubber is used as a sacrificial liner.

As the rubber wears, the tolerances within the unit become larger meaning the pump becomes less efficient. Designs have front and rear adjustment to reduce internal clearances to improve unit efficiency as they wear.

.png)