Model Number: SVF-3Q

Certificate: CE/ISO

Place of Origin: Hebei,China

Minimum Order Quantity: 1set

Delivery Time: 10-14 days

Payment Terms: T/T 100% deposit

Supply Ability: 500 sets per month

Packaging Details: Wooden crate

Vertical Tank Froth Pump

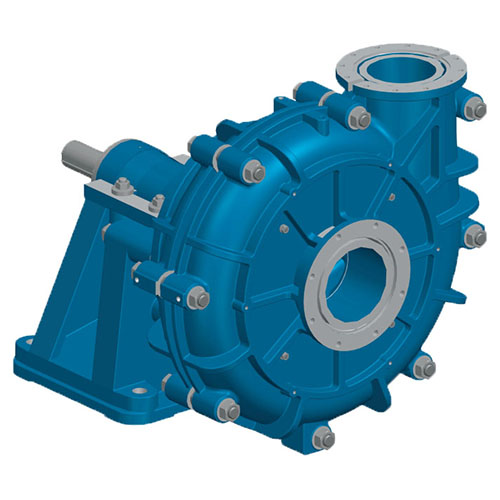

● Color: Blue

● Material: A05 high chrome iron alloy

● Function: Delivering foam slurries

● Type: Vertical

● Theory:Centrifugal

● Efficiency: Max.55

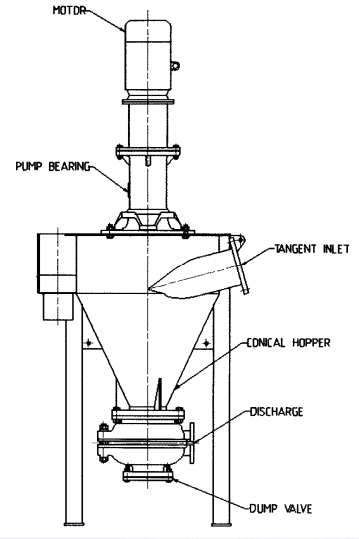

The type ‘SVF’ Froth Pump is a vertical pump complete with hopper which utilises casings and liners from the Type ‘MSH’ pumps.

It is designed to pump frothy slurries more efficiently by de-aerating or partially de-aerating the froth before it enters the pump head, utilising an induced vortex principal.

The ‘MSF’ range is available in sizes ranging from 50mm up to 200mm discharge diameter.

Pump Model: SVF

Hard metal vertical froth pumps SVF series have been designed to increase the pumpability of frothy slurry. The principle of operation is similar to that of hydrocyclone separation.

Standard pumps are supplied with parts in wear resistant high chrome iron alloy, with a nominal hardness of 58-65HRC.

The SVF froth pump is ideal for all applications involving handling of air entrained slurries, such as flotation froth in base metal concentrators, phosphate and apatite washing plants and calcium carbonate upgrading plants. The pump can also be used as a mixing and distribution unit, where dry powder has to be mixed with water.

Specifications:

| Pump Model | Allowable Max. Power (kw) | Material | Clear Water Performance | Diameter | ||||

| Capacity Q | Head H(m) | Speed n(r/min) | Max.Eff. η% | Suction (mm) | Discharge (mm) | |||

| Impeller | m3/h | |||||||

| SVF-2Q | 15 | Metal (A05) | 7.6-42.8 | 6-29.5 | 800-1800 | 45 | 100 | 50 |

| SVF-3Q | 18.5 | 23-77.4 | 5-28 | 700-1500 | 55 | 150 | 75 | |

| SVF-4R | 37 | 33-187.2 | 5-28 | 500-1050 | 55 | 150 | 100 | |

| SVF-6R | 75 | 80-393 | 5-25 | 250-680 | 55 | 200 | 150 | |

| SVF-8S | 110 | 126-575 | 5.5-25.5 | 350-650 | 55 | 250 | 200 | |

Projects with SV F Frothy Pumps:

Related Products

Yes, we are a manufacturer of slurry pump in China since 2008.

Yes, OEM/ODM are available.

T/T Bank Wiring, L/C, Western Union, Moneygram, Paypal.

By sea, air, railway.

Slurry pumps typically have a volute casing which is rubber lined, as well as a rubber lined impeller in order to minimise wear to internal metal parts. As slurries can be highly abrasive, and travel at high velocity the rubber is used as a sacrificial liner.

As the rubber wears, the tolerances within the unit become larger meaning the pump becomes less efficient. Designs have front and rear adjustment to reduce internal clearances to improve unit efficiency as they wear.

.png)