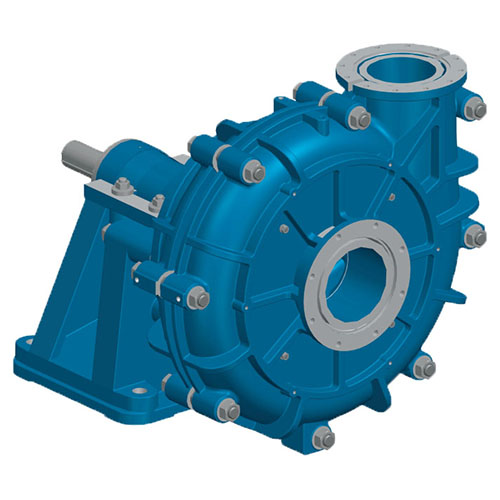

Product features:

This series of pumps are of single-stage, single suction, cantilever and horizontal structure. The pump body, pump cover and adapter plate are connected by clamps. Grease lubrication is adopted. It is mainly used for the transportation of strong abrasive materials whose particles are too large to be transported by general slurry pump. The pump and drive machine can be directly connected, V-belt drive, hydraulic coupling drive and reducer drive. The pump has the advantages of 360 ° abrasion resistance and convenient installation in any direction. The inlet of each type of pump is horizontal. From the transmission direction, the pump rotates clockwise or counterclockwise as required.

Application fields:

It is widely used in coal, electric power, transportation, river dredging, municipal engineering and other fields. This type of pump is suitable for conveying gravel, mud and slag slurry with large solid particles. It is also used for river sand mining and mining vessels.

Related Products

Yes, we are a manufacturer of slurry pump in China since 2008.

Yes, OEM/ODM are available.

T/T Bank Wiring, L/C, Western Union, Moneygram, Paypal.

By sea, air, railway.

Slurry pumps typically have a volute casing which is rubber lined, as well as a rubber lined impeller in order to minimise wear to internal metal parts. As slurries can be highly abrasive, and travel at high velocity the rubber is used as a sacrificial liner.

As the rubber wears, the tolerances within the unit become larger meaning the pump becomes less efficient. Designs have front and rear adjustment to reduce internal clearances to improve unit efficiency as they wear.

.png)