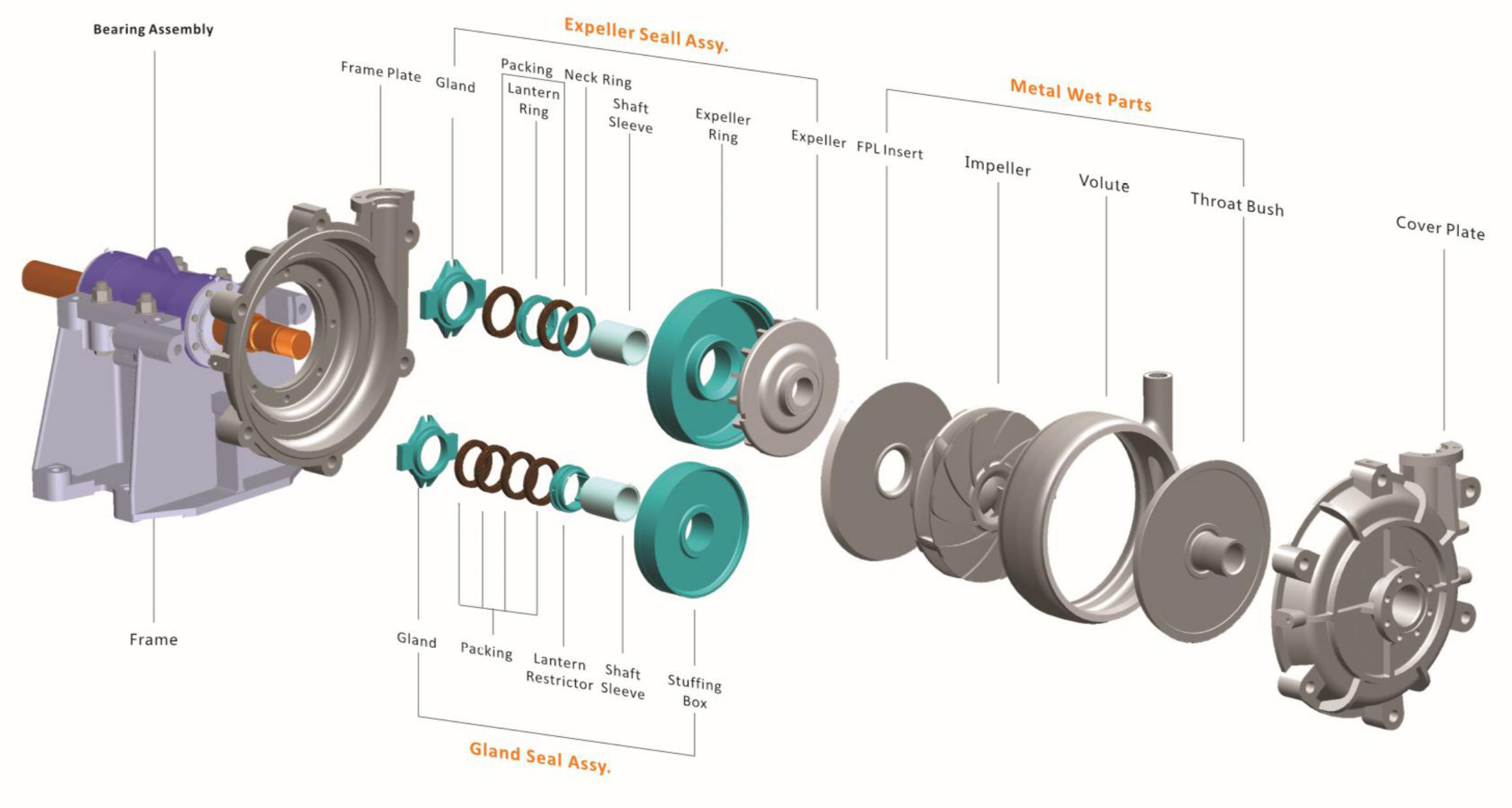

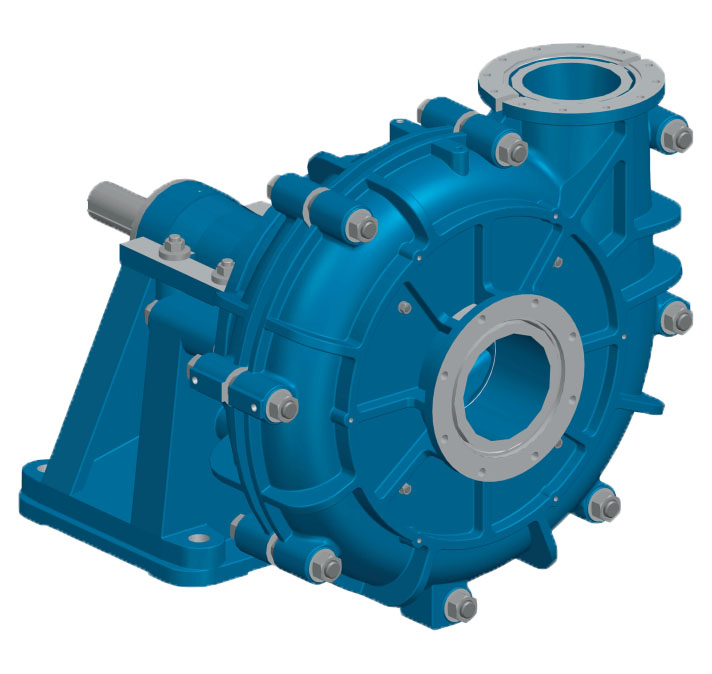

Heavy Duty Industrial Mining Mineral Centrifugal Slurry Pump Spare Parts

Discharge size range: 25mm to 450mm [1’’ to 18’’]

Flowrates to: 5000m3/hr [22,000GPM] Heads to: 73m [240ft]

The heavy duty MSH pump range is designed to perform continuous pumping of highly abrasive slurries. This range of pumps have been proved successful in processes from hydrocyclone feed to regrind, flotation and tailings in minerals processing plants as well as other industrial applications.

- Size: 8″ x 6″

- The capacity is 360-828m3/h.

- Head: 10-61m

- 500-1140rpm maximum speed

- NPSHr range: 2-9m

- Eff.: 72%

- Maximum power: 300kw

- Solids handling: 63mm

- Seal configuration: packing seal, evaporator seal, mechanical seal

- Materials include high chromium alloy, rubber, polyurethane, ceramic, and others.

Applications of Slurry Pumps

Slurry pumps have wide-ranging applications in various industries where large volumes of abrasive or high solids fluids need to be handled:

Mining: Slurry transportation in copper, gold, coal and other types of mines from the concentrator to processing plant. Also tailings disposal.

Dredging: Underwater sediment and sludge pumping required in dredging projects to create waterways or reclaim land.

Desalination: Transfer of thick slurries during the desalination process to extract freshwater from seawater.

Fracking: Handling water-based bentonite clay or drill cuttings slurry in upstream oil and gas fracking operations.

Wastewater treatment: Pumping sewage sludge between different process units at municipal wastewater plants.

Pulp and paper: Moving cellulose fiber slurries with consistencies over 10% concentration between processes.

Cement and minerals: Slurries encountered when processing ores, limestone and other minerals into final products.

Food processing: Viscous slurries that occur in processes like tomato concentrate production, beer brewing, sugar beet refining among others.

Related Products

Yes, we are a manufacturer of slurry pump in China since 2008.

Yes, OEM/ODM are available.

T/T Bank Wiring, L/C, Western Union, Moneygram, Paypal.

By sea, air, railway.

Slurry pumps typically have a volute casing which is rubber lined, as well as a rubber lined impeller in order to minimise wear to internal metal parts. As slurries can be highly abrasive, and travel at high velocity the rubber is used as a sacrificial liner.

As the rubber wears, the tolerances within the unit become larger meaning the pump becomes less efficient. Designs have front and rear adjustment to reduce internal clearances to improve unit efficiency as they wear.

.png)