Product features:

MSH series slurry pump is a new generation of heavy-duty slurry pump developed by our company on the basis of digesting and absorbing the imported ah series products, combined with our more than 70 years of slurry pump design and manufacturing experience and using advanced design means. It completely covers ah series products in terms of performance, with higher efficiency and better suction performance. It has the characteristics of high efficiency and energy saving, low vibration, low noise, reliable operation, long service life and convenient maintenance.

![G Brochure[1]-3.jpg G Brochure[1]-3.jpg](/upload/image/20240220/17083701117931242.jpg)

Application fields:

It is applicable to the transportation of strong abrasion and high concentration of solid particles in power, metallurgy, coal, building materials and other industries, such as hydraulic ash removal in thermal power plants, slurry transportation in metallurgical concentrators, coal slurry and heavy medium transportation in coal washing plants, etc. The maximum slurry weight concentration CW of the allowed solid-liquid mixture is: ash (slag) slurry and coal slurry 45%; Pulp and heavy medium 60%.

Type

| Warman | Allowable Mating Max Power (kw)

| Material 材料 | 清水性能Clear water performace | 叶轮Impeller | |||||||

Liner 护套 | Impel 叶轮 | 流量 Q Capacity | Head(m) 扬程 | Speed (r/min) 转速 | Max Efficacy h%

| NPSH (m) 汽蚀 余量 | No of Vanes 叶片数 | Impel Dia (mm) 叶轮直径 | ||||

(m3/h) | (I/S) | |||||||||||

MSH-1B | 1.5/1B-AH | 15 | M | M | 12.6-28.8 | 3.5-8 | 6-68 | 1200-3800 | 40 | 2-4 | 5 | 152 |

RSH-1B | 1.5/1B-AHR | RU | RU | 10.8-25.2 | 3-7 | 7-52 | 1400-3400 | 35 | 3 | |||

MSHH-1C | 1.5/1C-HH | 30 | M | M | 16.2-34.2 | 4.5-9.5 | 25-92 | 1400-2200 | 20 | 2-5.5 | 5 | 330 |

MSH-1.5B | 2/1.5B-AH | 15 | M | M | 32.4-72 | 9-20 | 6-58 | 1200-3200 | 45 | 3.5-8 | 5 | 184 |

RSH-1.5B | 2/1.5B-AHR | RU | RU | 25.2-54 | 7-15 | 5.5-41 | 1000-2600 | 50 | 2.5-5 | 178 | ||

MSH-2C | 3/2C-AH | 30 | M | M | 39.6-86.4 | 11-24 | 12-64 | 1300-2700 | 55 | 4-6 | 5 | 214 |

RSH-2C | 3/2C-AHR | RU | RU | 36-75.6 | 10-21 | 13-46 | 1300-2300 | 60 | 2-4 | 213 | ||

MSHH-2D | 3/2D-HH | 60 | M | M | 68.4-136.8 | 19-38 | 25-87 | 850-1400 | 47 | 3-7.5 | 5 | 457 |

MSH-3C | 4/3C-AH | 30 | M | M | 86.4-198 | 24-55 | 9-52 | 1000-2200 | 71 | 4-6 | 5 | 245 |

RSH-3C | 4/3C-AHR | RU | RU | 79.2-180 | 22-50 | 5-34.5 | 800-1800 | 59 | 3-5 | |||

MSHH-3E | 4/3E-HH | 120 | M | M | 126-252 | 35-70 | 12-97 | 600-1400 | 50 | 2-5 | 5 | 508 |

MSH-4D | 6/4D-AH | 60 | M | M | 162-360 | 40-100 | 12-56 | 800-1550 | 65 | 5-8 | 5 | 365 |

RSH-4D | 6/4D-AHR | RU | RU | 144-324 | 40-90 | 12-45 | 800-1350 | 65 | 3-5 | |||

MSH-6E | 8/6E-AH | 300 | M | M | 360-828 | 100-230 | 10-61 | 500-1140 | 72 | 2-9 | 5 | 510 |

8/6E-AHR | RU | RU | 324-720 | 90-200 | 7-49 | 400-1000 | 65 | 5-10 | 5 | 510 | ||

MSM-8E | 10/8E-M | 120 | M | M | 666-1440 | 185-400 | 14-60 | 600-1100 | 73 | 4-10 | 5 | 549 |

MSH-8ST | 10/8ST-AH | 560 | M | M | 612-1368 | 170-380 | 11-61 | 400-850 | 71 | 4-10 | 5 | 686 |

RU | RU | 540-1188 | 150-330 | 12-50 | 400-750 | 75 | 4-12 | |||||

MSH-10ST | 12/10ST-AH | 560 | M | M | 936-1980 | 260-550 | 7-68 | 300-800 | 82 | 6 | 5 | 762 |

RU | RU | 720-1620 | 200-450 | 7-45 | 300-650 | 80 | 2.5-7.5 | |||||

MSH-12ST | 14/12ST-AH | 560 | M | M | 1260-2772 | 350-770 | 13-63 | 300-600 | 77 | 3-10 | 5 | 965 |

RU | RU | 1152-2520 | 320-700 | 13-44 | 30-500 | 79 | 3-8 | |||||

MSH-14TU | 16/14TU-AH | 1200 | M | M | 1368-3060 | 380-850 | 11-63 | 250-50 | 79 | 4-10 | 5 | 1067 |

MSH-18TU | 20/18TU-AH | 1200 | M | M | 2520-5400 | 700-1500 | 13-57 | 200-400 | 85 | 5-10 | 5 | 1370 |

Related Products

Yes, we are a manufacturer of slurry pump in China since 2008.

Yes, OEM/ODM are available.

T/T Bank Wiring, L/C, Western Union, Moneygram, Paypal.

By sea, air, railway.

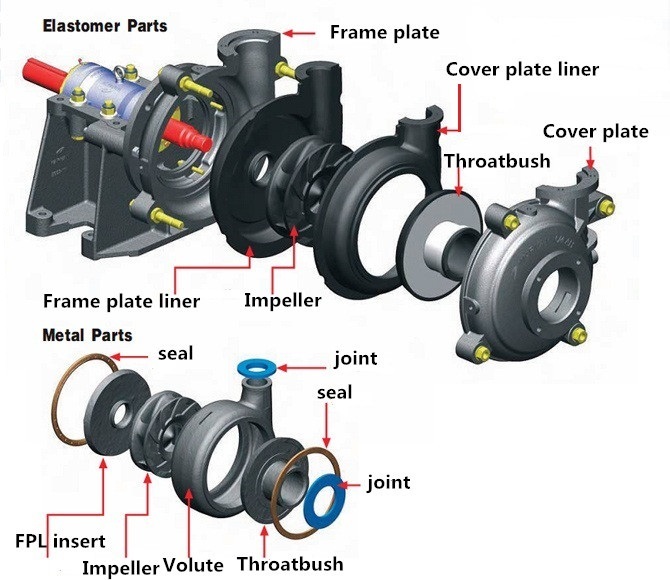

Slurry pumps typically have a volute casing which is rubber lined, as well as a rubber lined impeller in order to minimise wear to internal metal parts. As slurries can be highly abrasive, and travel at high velocity the rubber is used as a sacrificial liner.

As the rubber wears, the tolerances within the unit become larger meaning the pump becomes less efficient. Designs have front and rear adjustment to reduce internal clearances to improve unit efficiency as they wear.

.png)