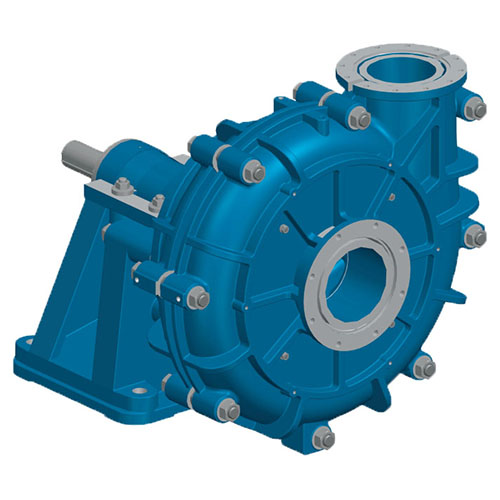

Product features:

The structure of this series of pumps is simple. The dredge pump with diameter below 500wn adopts the horizontal structure of single pump shell and single-stage single suction cantilever. According to the connection mode of gearbox, two typical structures can be provided, that is, the self-contained bracket type is combined with the pump box, the self-contained bracket type lubrication mode is grease lubrication or oil lubrication, and the shaft seal adopts mechanical seal or mechanical seal and packing composite seal. The WN type cabin pump of dredging pump with diameter above 600 adopts the horizontal structure of double pump shell, single-stage and single suction cantilever, with its own bracket, and the lubrication method is forced thin oil lubrication; Wnq underwater dredging pump adopts single pump shell structure to reduce the pump weight and facilitate lifting and movement. All diameter dredge pump shaft seals can adopt spiral sleeve L-shaped rubber seal. The sealing device is composed of three L-shaped sealing rings and a threaded shaft sleeve. In order to improve the service life of shaft seal, sand water separator can be equipped to ensure the quality of shaft seal water.

This series of pump has good cavitation performance, which ensures the strong suction capacity of the pump, and can achieve greater excavation depth and higher inhalable concentration at the same time; The impeller has large channel width and strong flow capacity; The steep drop of performance curve makes the sludge pump more adaptable to the change of discharge distance; By changing the pump speed or changing the impeller diameter, a variety of allocation of pump performance can be realized.

Application fields:

It is mainly used for trailing suction dredger and cutter suction dredger. It is also used for river sand mining and mining vessels.

Related Products

Yes, we are a manufacturer of slurry pump in China since 2008.

Yes, OEM/ODM are available.

T/T Bank Wiring, L/C, Western Union, Moneygram, Paypal.

By sea, air, railway.

Slurry pumps typically have a volute casing which is rubber lined, as well as a rubber lined impeller in order to minimise wear to internal metal parts. As slurries can be highly abrasive, and travel at high velocity the rubber is used as a sacrificial liner.

As the rubber wears, the tolerances within the unit become larger meaning the pump becomes less efficient. Designs have front and rear adjustment to reduce internal clearances to improve unit efficiency as they wear.

.png)