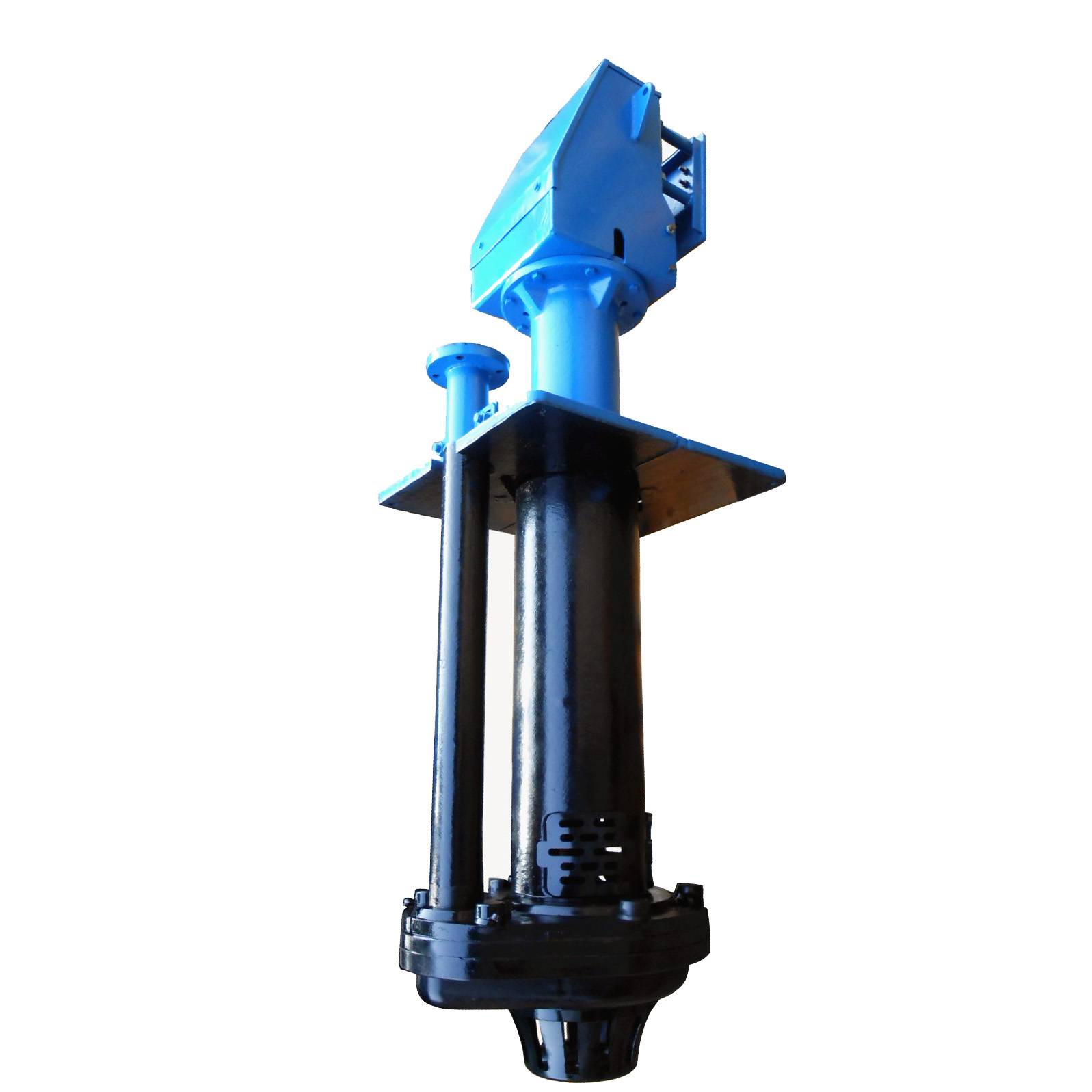

The RSV heavy duty cantilever sump pump is designed for applications requiring greater reliability and durability than conventional vertical process pumps can offer. The heavy duty catilever design makes the RSV sump pump ideally suited for heavy continous handling of corrosive liquids and slurries whilst submerged in sumps or pits. The rugged RSV heavy duty sump pumps are available in a wide range of popular sizes to suit most pumping applications. Thousands of these pumps are proving their reliability and efficiency worldwide in:

Minerals Processing

Coal Preparation

Chemical Processing

Effluent Handling

Sand and Gravel

and almost every other tank, pit or hole-in-the-ground slurry handling situation. The SVR design with elastomer covered components makes it ideal for: Corrosive slurries; Large Particle sizes; High density slurries; Heavy duties demanding cantilever shafts.

Material Construction:

| Description | Standard Material | Optional Material |

| Impeller | Natural Rubber R55 | |

| Casing | Natural Rubber R55 | |

| Back Liner | Natural Rubber R55 | |

| Shaft | Carbon Steel | SUS304, SUS316(L) |

| Discharge Pipe | 20# Mild Steel | SUS304, SUS316(L) |

| Column | 20# Mild Steel | SUS304, SUS316(L) |

Specifications:

Pump | Allowable | Material | Clear Water Performance | Impeller | |||||

Capacity Q | Head | Speed | Max.Eff. | Length | No. of | Vane Dia. | |||

Impeller | m3/h | ||||||||

RSV-40P | 15 | Rubber | 19.44-43.2 | 4.5-28.5 | 1000-2200 | 40 | 900 | 5 | 195 |

RSV-65Q | 30 | 23.4-111 | 5-29.5 | 700-1500 | 50 | 1200 | 290 | ||

RSV-100R | 75 | 54-289 | 5-35 | 500-1200 | 56 | 1500 | 390 | ||

RSV-150S | 110 | 72-504 | 10-35 | 500-1000 | 56 | 1800 | 480 | ||

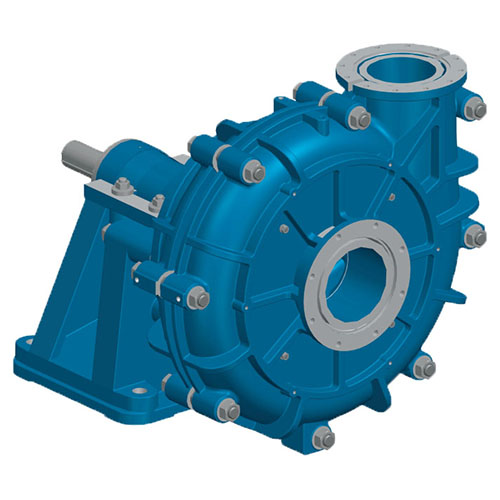

Related Products

Yes, we are a manufacturer of slurry pump in China since 2008.

Yes, OEM/ODM are available.

T/T Bank Wiring, L/C, Western Union, Moneygram, Paypal.

By sea, air, railway.

Slurry pumps typically have a volute casing which is rubber lined, as well as a rubber lined impeller in order to minimise wear to internal metal parts. As slurries can be highly abrasive, and travel at high velocity the rubber is used as a sacrificial liner.

As the rubber wears, the tolerances within the unit become larger meaning the pump becomes less efficient. Designs have front and rear adjustment to reduce internal clearances to improve unit efficiency as they wear.

.png)