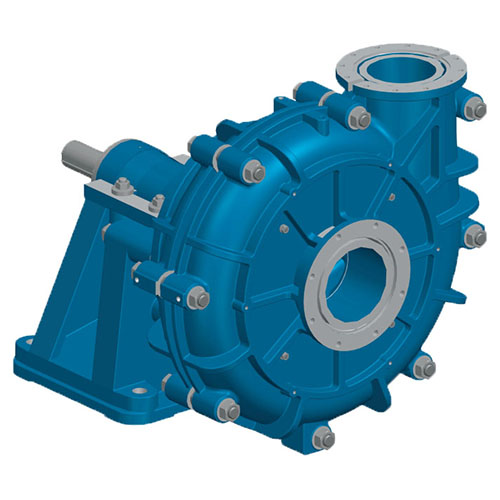

Polyurethane (Blue) Impeller

Erosive Resistant Polyurethane Slurry Pump Components: Wet end Parts – Impeller (E4147U01) Physical and Mechanical Performance Parameters of Polyurethane 1 Test Status 23±2°C Unit Measured Value Executive Standard 1.1 Hardness (Shore A) Degree 75 GB/T2411-2008 1.2 Tensile Strength MPa 48 GB/T528-2009 1.3 100% Tensile Stress MPa 4.1 GB/T528-2009 1.4 300% Tensile Stress MPa 8.2 GB/T528-2009 1.5 Elongation % 600 GB/T...

Erosive Resistant Polyurethane Slurry Pump Components: Wet end Parts – Impeller (E4147U01)

Physical and Mechanical Performance Parameters of Polyurethane

1 | Test Status 23±2°C | Unit | Measured Value | Executive Standard |

1.1 | Hardness (Shore A) | Degree | 75 | GB/T2411-2008 |

1.2 | Tensile Strength | MPa | 48 | GB/T528-2009 |

1.3 | 100% Tensile Stress | MPa | 4.1 | GB/T528-2009 |

1.4 | 300% Tensile Stress | MPa | 8.2 | GB/T528-2009 |

1.5 | Elongation | % | 600 | GB/T528-2009 |

1.6 | Resilience | % | 46 | GB/T1681-2009 |

1.7 | Tear Strength | KN/m | 85 | GB/T529-2009 |

Related Products

Yes, we are a manufacturer of slurry pump in China since 2008.

Yes, OEM/ODM are available.

T/T Bank Wiring, L/C, Western Union, Moneygram, Paypal.

By sea, air, railway.

Slurry pumps typically have a volute casing which is rubber lined, as well as a rubber lined impeller in order to minimise wear to internal metal parts. As slurries can be highly abrasive, and travel at high velocity the rubber is used as a sacrificial liner.

As the rubber wears, the tolerances within the unit become larger meaning the pump becomes less efficient. Designs have front and rear adjustment to reduce internal clearances to improve unit efficiency as they wear.

.png)