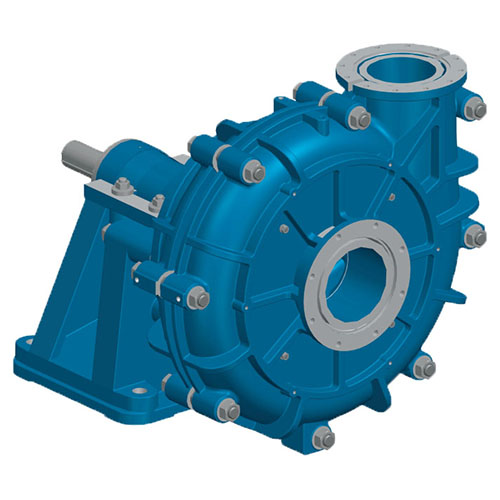

MSH-4D is equivalent to 6/4D-AH, a 4” discharge slurry pump, which is also our best seller among our MSH series Heavy Duty slurry pumps. MSH series slurry pumps are specially desighed for highly abrasive slurries. The wet-end spare parts are available in materials high chrome alloy, or soft natural rubber or polyurethane. The shaft seals are available from gland packing seal, expeller seal and mechanical seal. The MSH series heavy duty horizontal slurry pumps offer a wide range of world class hard metal and rubber lined slurry pumps for abrasive pumping applications.

Material Construction:

| Part Description | Standard | Alternative |

| Impeller | A05 | A33, A49 |

| Volute Liner | A05 | A33, A49 |

| Front Liner | A05 | A33, A49 |

| Back Liner | A05 | A33, A49 |

| Split Outter Casings | Grey Iron | Ductile Iron |

| Shaft | Carbon Steel | SS304, SS316 |

| Shaft Sleeve | SS304 | SS316, Ceramic, Tungstan Carbide |

| Shaft Seal | Expeller Seal | Gland Packing, Mechanical Seal |

| Bearings | ZWZ, HRB | SKF, Timken, NSK etc. |

Applications:

Lime Slurry; Pulp and Paper; Alumina; Fertilizer; In-Plant Slurry Transfer etc.

Specifications:

| Pump Model | OEM Model | Base Type | Bearing Assembly | Power (Kw) | Flow(m3/h) | Head(m) | Speed(rpm) | Max.Effi. |

| MSH-4D | 6/4D-AH | D | DAM005M | 60 | 162-360 | 12-56 | 800-1550 | 65% |

| MSH-4DD | 6/4DD-AH | DD | DDAM005M | 110 | ||||

| MSH-4E | 6/4E-AH | E | E005M | 120 | ||||

| MSH-4EE | 6/4EE-AH | EE | EE005M | 225 |

Performance Curve with Standard Impeller, Metal 5-Vane HXE4147A05:

Related Products

Yes, we are a manufacturer of slurry pump in China since 2008.

Yes, OEM/ODM are available.

T/T Bank Wiring, L/C, Western Union, Moneygram, Paypal.

By sea, air, railway.

Slurry pumps typically have a volute casing which is rubber lined, as well as a rubber lined impeller in order to minimise wear to internal metal parts. As slurries can be highly abrasive, and travel at high velocity the rubber is used as a sacrificial liner.

As the rubber wears, the tolerances within the unit become larger meaning the pump becomes less efficient. Designs have front and rear adjustment to reduce internal clearances to improve unit efficiency as they wear.

.png)